The products here are part of DADISICK's brand product line, which is independently developed, manufactured, and sold.

We provide stable, high-quality products and ensure fast delivery.

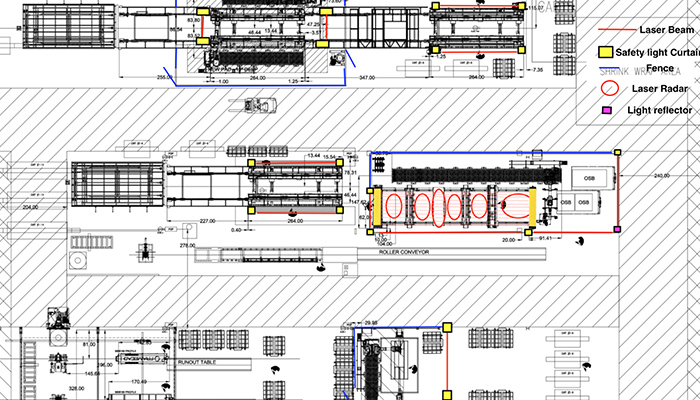

The cold stamping industry encompasses various manufacturing processes that involve shaping and forming metal sheets without the use of heat. In this context, safety light curtains play a crucial role in ensuring the protection of workers and preventing accidents. One primary application of safety light curtains in the cold stamping industry is perimeter guarding.

Model: QT32-20-620-2BB1. Nowadays, safety infrared grating protector plays a crucial protective role in stamping automotive metal parts using press machines. The installation of this device adds an additional layer of safety measures to ensure the well-being of operators and prevent accidents or injuries.

Model: QS30/20-580 WIt is necessary to installing safety light curtain on a flat vulcanization machine to enhance safety in the workplace. Here are a few reasons why it is important: 1. Hazard Detection: A safety light curtain can detect when an object or person enters a hazardous area near the machine It uses infrared beams of light to create an invisible barrier.

Model: QS22/20-420 WSafety light curtains are an important measure to ensure the safety of workers in the automotive forging department. Here is the choosing and installation procedure for your reference: 1. Assess the area: Start by understanding the layout and requirements of the automotive forging department.

Model: QS32/20-620 WInstalling safety light curtains on hydraulic presses provides several advantages. First and foremost, they greatly enhance the safety of the workplace by acting as a protective barrier between the operator and the hazardous machine.

Model: QCE20/20-380 2BBInstalling safety light curtain is an excellent idea to enhance safety of forging press in the workplace. Here are the general steps of choosing and installation you can follow: 1. Assess the requirements: Understand the specific safety needs of your forging press setup and determine the appropriate type, size, and location for the safety light curtain.

Model: QCE20/20-380 2BB

Tell us your requirements, our application engineers will help you find the right solution