Which Sensor Is Used For Double Sheet Monitoring

Common Sensor Types For Double Sheet Monitoring

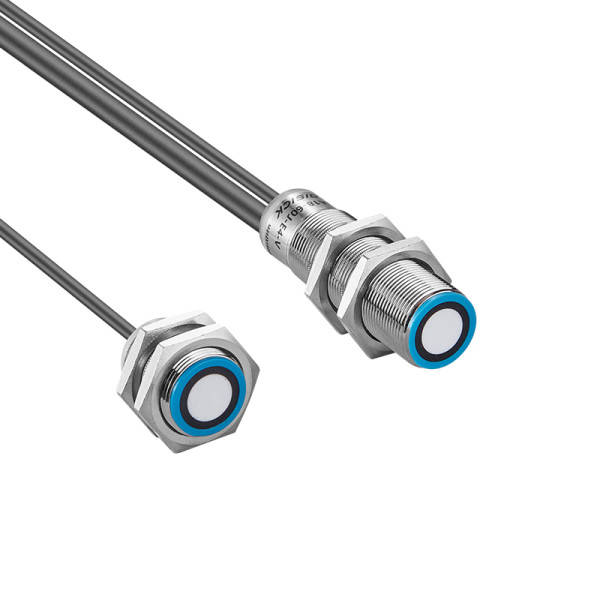

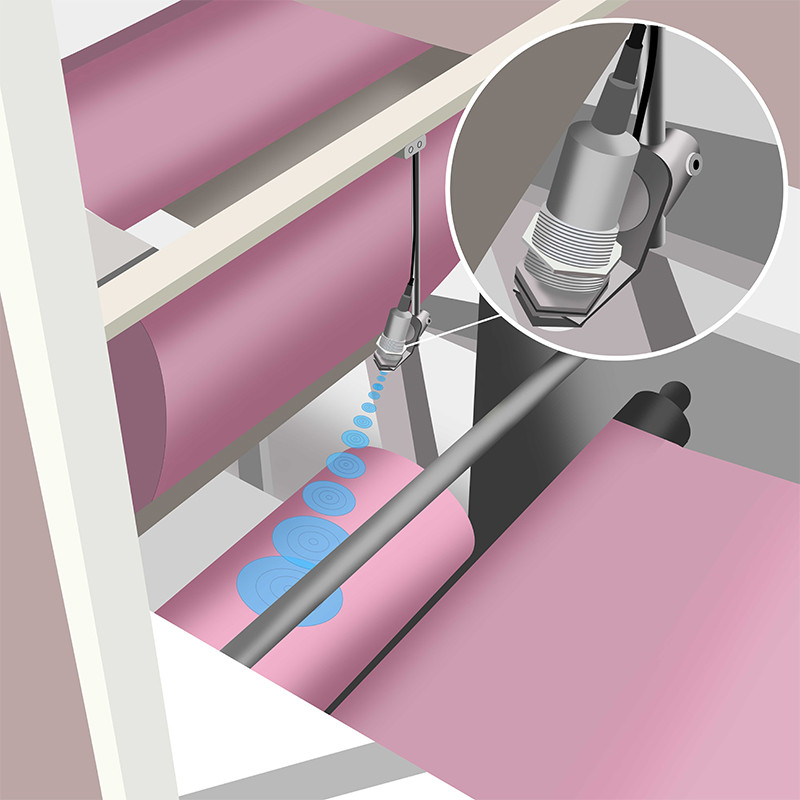

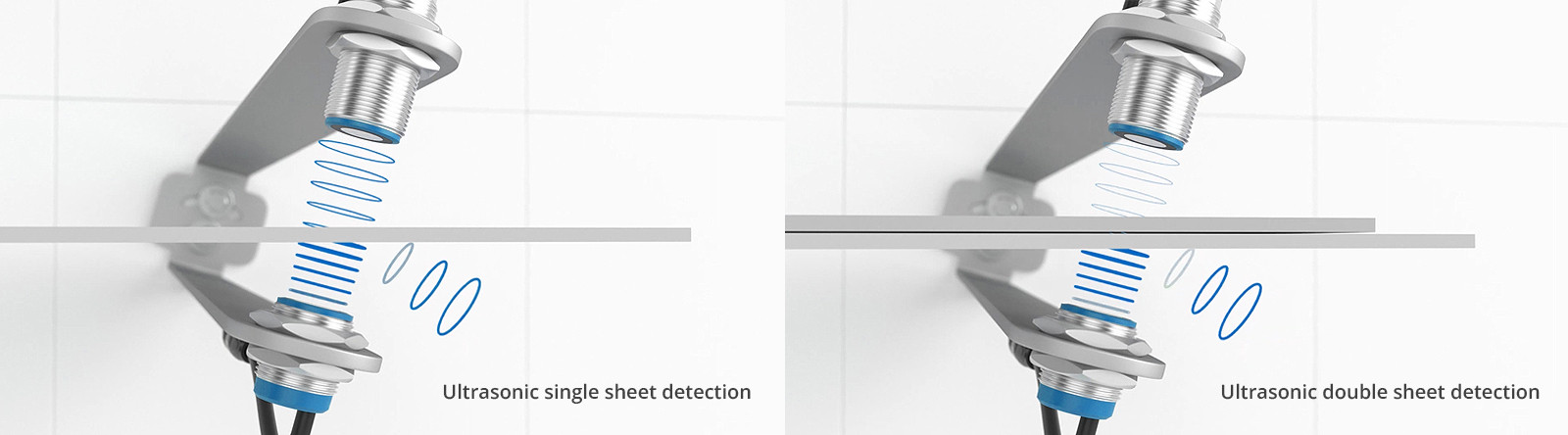

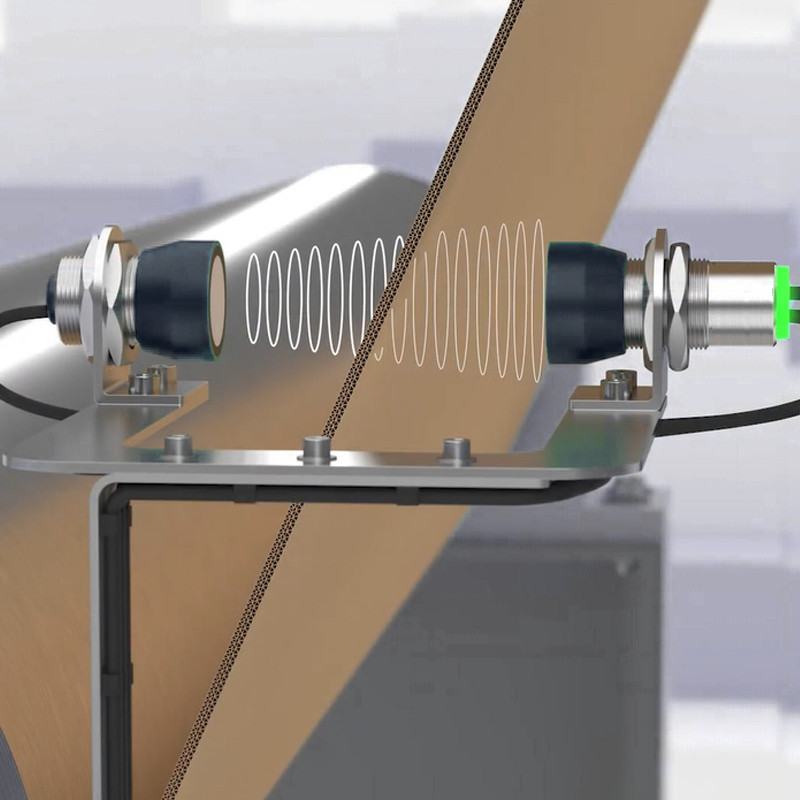

Ultrasonic double-sheet sensors

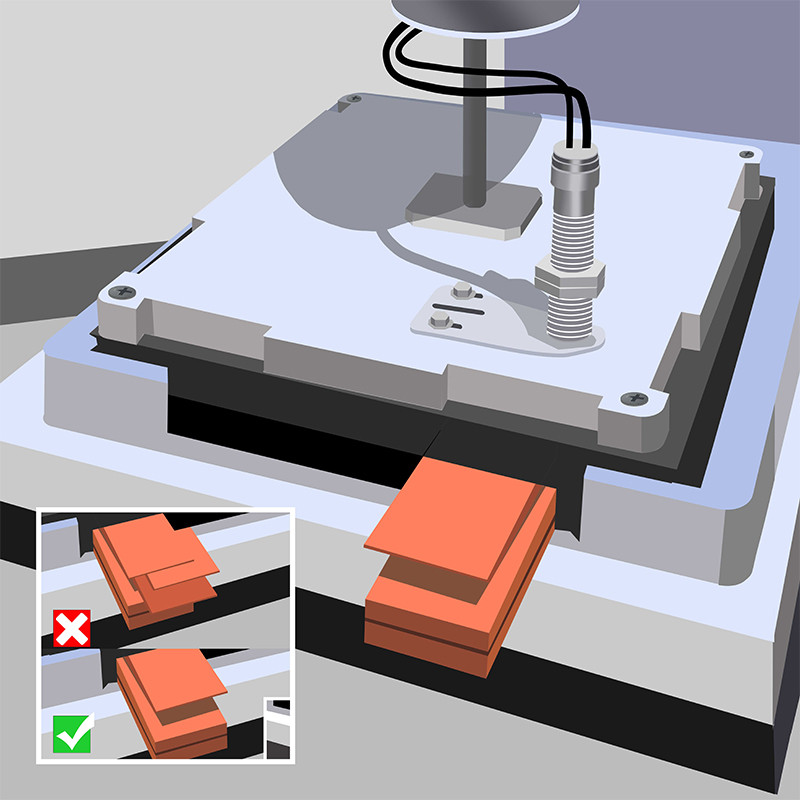

Capacitive / Dielectric sensors

Inductive / Magnetic sensors

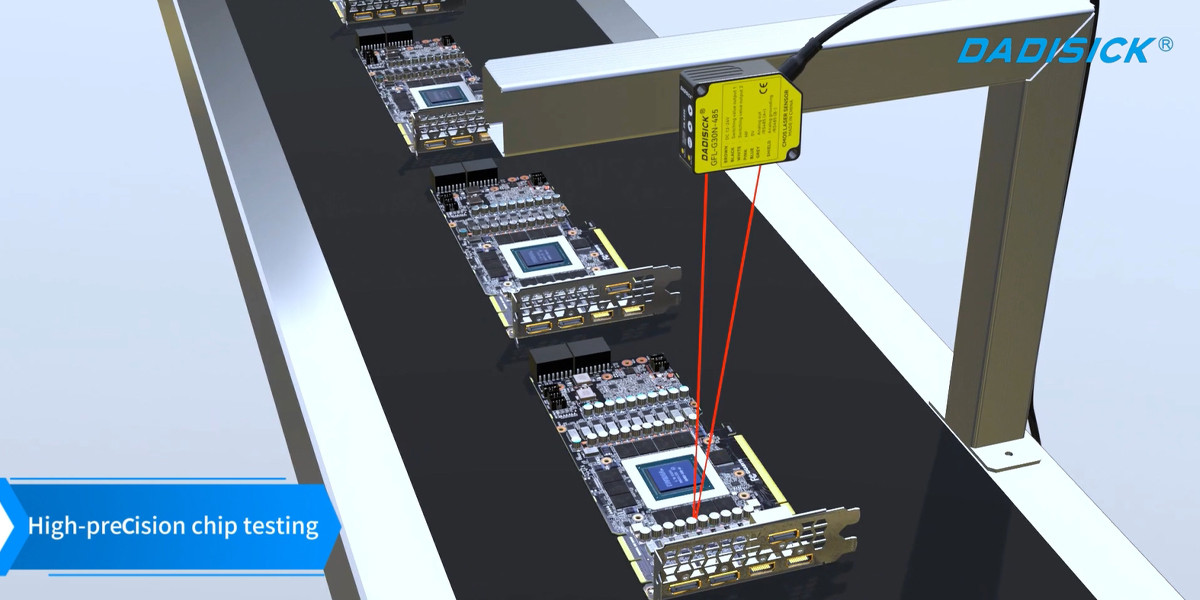

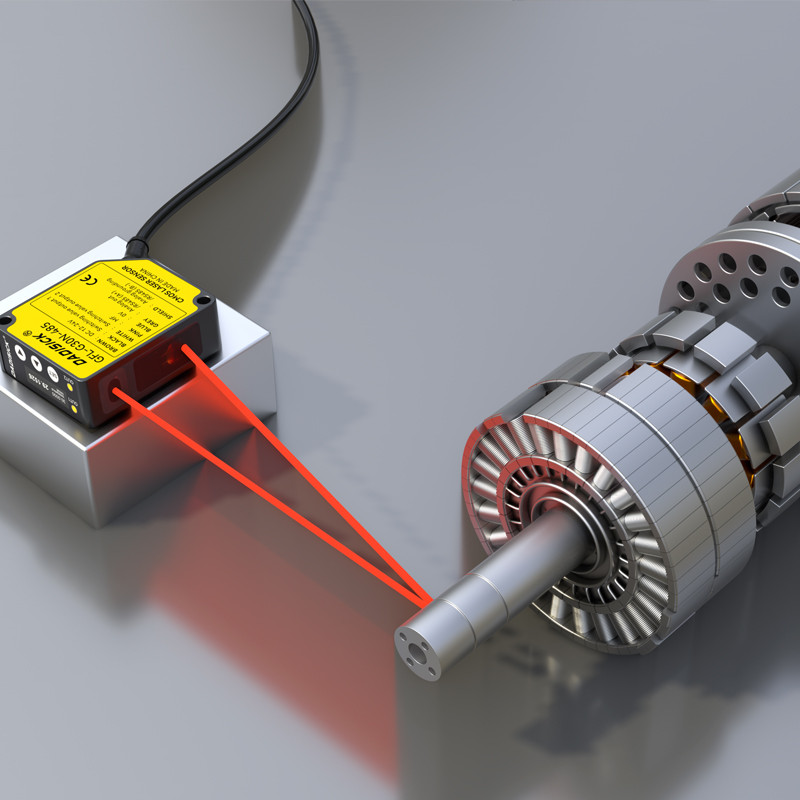

Optical / Laser displacement and vision-based methods

How Ultrasonic Double Sheet Sensors Work?

Material-To-Technology Mapping

Selection Checklist — Questions To Answer Before Choosing A Sensor

2. How thin are the sheets / how small is the thickness difference between single & double? — Very thin differences may need high-frequency ultrasonic or capacitive sensors.

3. Is the material printed, colored, or transparent? — If yes and optical is unreliable, ultrasonic is a strong choice.

4. Is the process high-speed or continuous web feeding? — Ensure sensor response time and repeatability match line speed.

5. Installation constraints (space, mounting one-sided vs two-sided)? — Some detectors require through-beam pairs; some product lines offer single-sided measurement or specialized mounting.

Practical Installation & Tuning Tips

● Teach/calibrate on production sample: Calibrate thresholds using actual production stock (single sheet, double sheet, and empty). Many commercial units provide remote/automatic calibration.

● Noise & vibration: Use damped mounts or shielding if the press/feeder environment vibrates heavily — vibration can affect amplitude readings.

● Environmental factors: Temperature, humidity, and dust can affect capacitive and, to lesser degree, ultrasonic performance. Account for environment in sensor choice and enclosure rating.

Quick Comparison

Sensor type | Pros | Cons | ||

Ultrasonic | non-contact, color-insensitive, good for many films/papers. | limited for very thin transparent layers in some cases. | ||

Capacitive | very sensitive to thin dielectric changes. | influenced by humidity/material composition; needs tuning. | ||

Inductive / Magnetic | best for metal. | not usable for non-conductive substrates. | ||

Optical / Laser / Vision | high precision for certain shapes/metal blanks. | affected by surface reflectivity/print; may need complex setup. | ||

FAQs

Q: Can one sensor type handle all materials?