Choosing the Right Safety Door Switch: A Comparative Guide to Non-Locking, Locking and Non-Contact Types

Basics of Safety Door Switches

• When selecting a safety door switch the critical factors include:

Three Types of Safety Door Switches

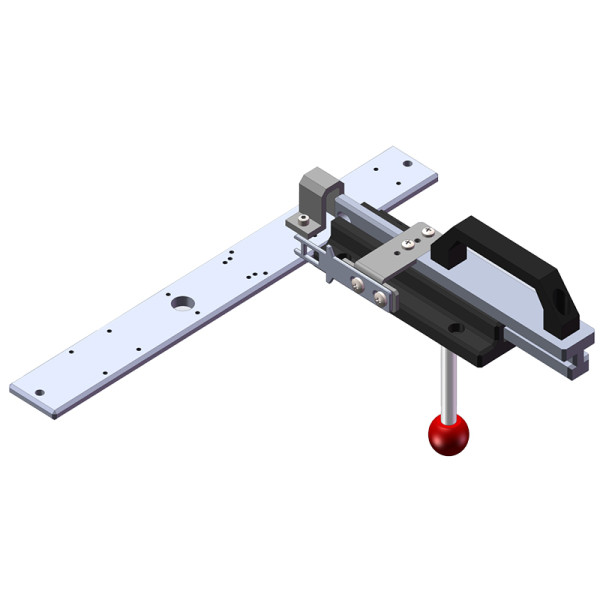

Non-Locking Type (no locking force)

| OX-D2 & OX-D3 Series | ||||

| Model | Contact composition (Door + Lock monitoring) | Head materials | Connection | Mechanical life |

| OX-D2-CO | CO (1NC+1NO) | Plastic | M20 | 1,000,000 times |

| OX-D2-2C | 2C (2NC) | |||

OX-D3-2CO | 2CO (2NC+1NO) | |||

OX-D3-3C | 3C (3NC) | |||

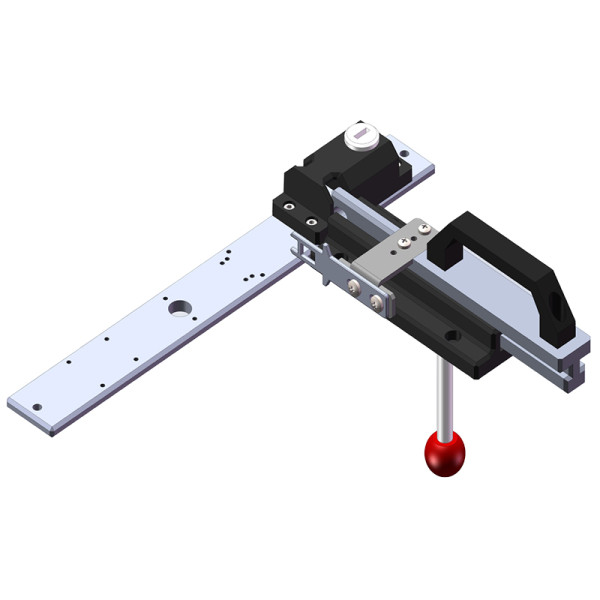

Locking Type (with locking force)

OX-W2 Series | ||||

| Lock/Release method | Model | Lock/Release method | Model | Contact composition (Door + Lock monitoring) |

| Solenoid Lock / Mechanical Release | OX-W2-CO/CO-GD-J | Mechanical Lock / Solenoid Release | OX-W2-CO/CO-GC-J | CO/CO (1NC/1NO+1NC/1NO) |

| OX-W2-CO/2C-GD-J | OX-W2-CO/2C-GC-J | CO/2C (1NC/1NO+2NC) | ||

OX-W2-2C/CO-GD-J | OX-W2-2C/CO-GC-J | 2C/CO (2NC+1NC/1NO) | ||

OX-W2-2C/2C-GD-J | OX-W2-2C/2C-GC-J | 2C/2C (2NC+2NC) | ||

OX-W2-C2O/C-GD-J | OX-W2-C2O/C-GC-J | C2O/C (1NC/2NO+1NC) | ||

OX-W2-3C/C-GD-J | OX-W2-3C/C-GC-J | 3C/C (3NC+1NC) | ||

OX-W2-2CO/C-GD-J | OX-W2-2CO/C-GC-J | 2CO/C (2NC/1NO+1NC) | ||

OX-W2-C/3C-GD-J | OX-W2-C/3C-GC-J | C/3C (1NC+3NC) | ||

OX-W2-C/C2O-GD-J | OX-W2-C/C2O-GC-J | C/C2O (1NC+1NC/2NO) | ||

OX-W2-C/2CO-GD-J | OX-W2-C/2CO-GC-J | C/2CO (1NC+2NC/1NO) | ||

OX-W2-O/3C-GD-J | OX-W2-O/3C-GC-J | O/3C (1NO+3NC) | ||

OX-W2-O/2CO-GD-J | OX-W2-O/2CO-GC-J | O/2CO (1NO+2NC/1NO) | ||

OX-W2-2C/2O-GD-J | OX-W2-2C/2O-GC-J | 2C/2O (2NC+2NO) | ||

OX-W2-2O/2C-GD-J | OX-W2-2O/2C-GC-J | 2O/2C (2NO+2NC) | ||

| OX-W3 Series | ||||

| Lock/Release method | Model | Lock/Release method | Model | Contact composition(Door + Lock monitoring) |

Solenoid Lock / Mechanical Release | OX-W3-C/C-GD-J | Mechanical Lock / Solenoid Release | OX-W3-C/C-GC-J | C/C (1NC+1NC) |

| OX-W3-/2C-GD-J | OX-W3-/2C-GC-J | /2C (2NC) | ||

OX-W3-2C/-GD-J | OX-W3-2C/-GC-J | 2C/ (2NC) | ||

OX-W3-CO/-GD-J | OX-W3-CO/-GC-J | CO / (1NC/1NO) | ||

OX-W3-O/C-GD-J | OX-W3-O/C-GC-J | O/C (1NO +1NC) | ||

| OX-W3-/CO-GD-J | OX-W3-/CO-GC-J | /CO (1NC/1NO) | ||

| OX-W5 Series | ||||

| Lock/Release method | Model | Lock/Release method | Model | Contact composition(Door + Lock monitoring) |

| Solenoid Lock / Mechanical Release | OX-W5-2CO/2CO-GD-J | Mechanical Lock / Solenoid Release | OX-W5-2CO/2CO-GC-J | 2CO/2CO(2NC/1NO+2NC/1NO) |

OX-W5-3C/2CO-GD-J | OX-W5-3C/2CO-GC-J | 3C/2CO (3NC+2NC/1NO) | ||

OX-W5-2CO/3C-GD-J | OX-W5-2CO/3C-GC-J | 2CO/3C (2NC/1NO+3NC) | ||

| OX-W5-3C/3C-GD-J | OX-W5-3C/3C-GC-J | 3C/3C (3NC+3NC) | ||

Non-Contact Type

Typical Applications

OX-R1 Series RFID Non-contact Safety Door Switch | |||

OX-R1-FN-S-P1 | 4-core direct wiring dual NPN output 2M line | ||

OX-R1-FP-S-P1 | 4-core direct wiring dual PNP output 2M line | ||

OX-R1-EN-S-P1 | 6-core direct wiring dual NPN output with cascade 2M line | ||

OX-R1-EP-S-P1 | 6-core direct wiring dual PNP output with cascade 2M line | ||

OX-R1-FN-D-P1 | 4-core direct wiring dual NPN output 2M line, Actuator with unique code | ||

OX-R1-FP-D-P1 | 4-core direct wiring dual PNP output 2M line, Actuator with unique code | ||

OX-R1-EN-D-P1 | 6-core direct wiring dual NPN output with cascade 2M line, Actuator with unique code | ||

OX-R1-EP-D-P1 | 6-core direct wiring dual PNP output with cascade 2M line, Actuator with unique code | ||

OX-C1 Series Coded Magnetic Non-Contact Safety Door Switch | |||

| OX-C1-2O-P1A | 2 Normally Open, Direct Cable Output, 2m | ||

| OX-C1-1C1O-P1A | 1 Normally Open, 1 Normally Closed, Direct Cable Output, 2m | ||

| OX-C1-2C-P1A | 2 Normally Closed, Direct Cable Output, 2m | ||

Comparative Summary & Selection Guidance

| Type | Locking Feature | Contact Mode | Suitable Environment | Typical Applications | Strengths | Weaknesses |

| Non Locking | None | Mechanical | Standard industrial | Low-risk guard monitoring | Low cost, simple | No lock protection, limited for high risk |

| Locking | Physical lock present | Mechanical + lock | Medium to high hazard | Large inertia machines, robots, presses | Strong protection | Higher cost & maintenance |

| Non-Contact | Detection only (optional lock) | Magnetic/optical | Harsh / cleaning / logistics | Food, pharma, logistics doors | Durable, minimal wear | May lack physical lock if not specified |