How to Choose the Right Non-contact Safety Switch: Types, Advantages, and Applications

What Is A Non-Contact Safety Switch?

Basic definition of non-contact safety switches

Working principle of non-contact safety switches

What Are The Different Types Of Non-Contact Safety Switches?

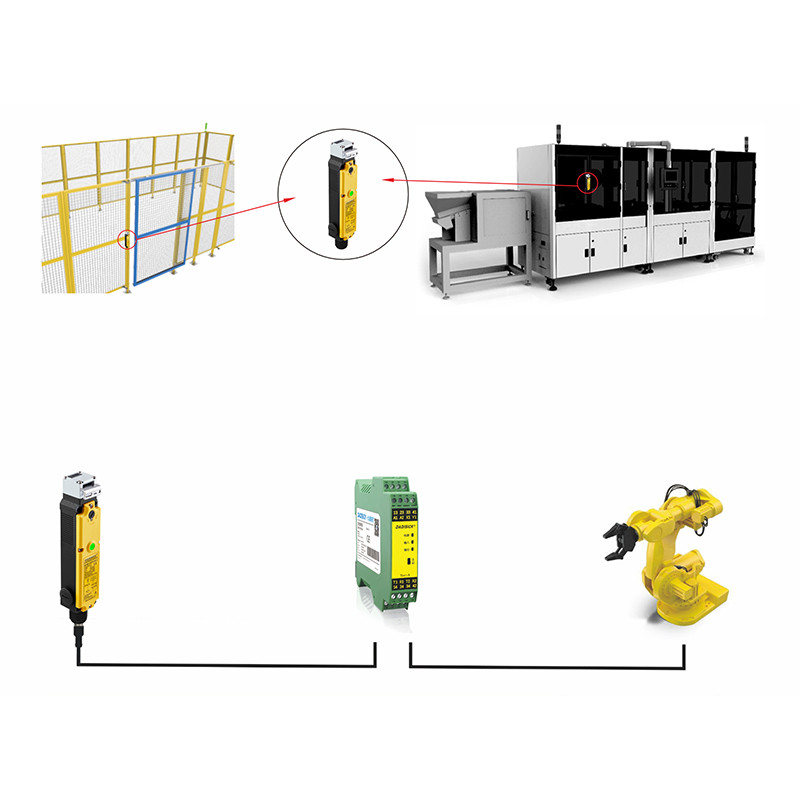

Applications of Non-Contact Safety Switches

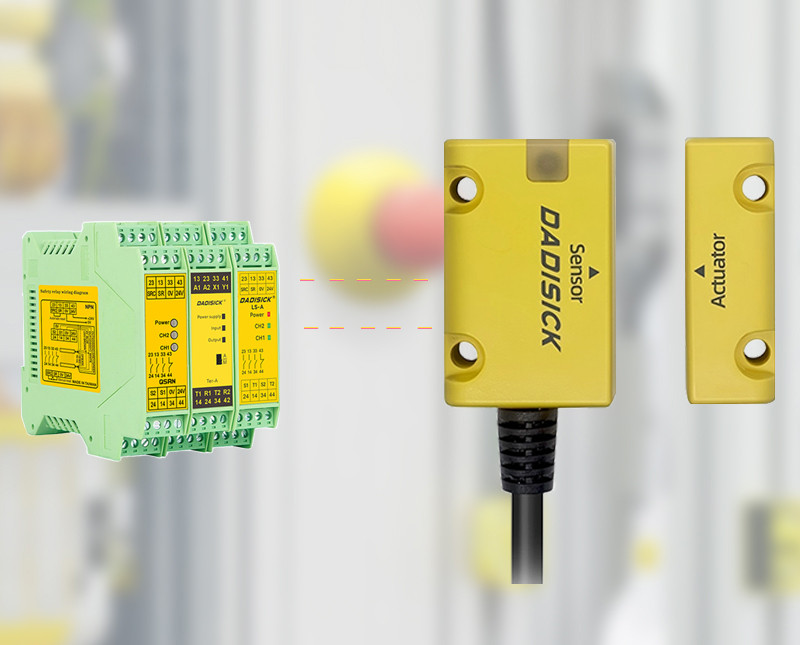

Recommended OX-R1 Series Non Contact RFIF Coded Safety Switches

The OX-R1 series RFID safety switches are based on RFID technology and offer advantages over mechanical or magnetic switches, including secure detection (with unique coding), strong interference resistance, and reliable safety. The use of safe dual-channel output technology achieves safety level PLe, effectively preventing false negatives, false positives, or unauthorized manual activation. These switches can be used in conjunction with safety door locks. | ||||

Safety standards | ISO13849-1, IEC/EN60947-5-1, IEC/EN60947-5-3 | |||

Safety classification | Class 4 switch with IS0 13849-1/suitable for PLe/PLd | |||

Certification | CE | |||

Horizontal distance | Conduction, min: 10 mm | |||

Vertical distance | Conduction, min: 8 mm | |||

Operating voltage | 24 V DC±15% | |||

Operating current | 30 mA | |||

Output current | 150 mA | |||

Response time | 60 ms | |||

Protection level | IP65, IP67 (customized)\IP68 (customized) | |||

Operating frequency | 1 Hz | |||

Operating temperature | -10 ~ +55℃ | |||

Relative humidity | 5 ~ 95% | |||

Material | Anti-flame retardant thermoplastic | |||

OX-R1-FN-S-P1 | 4-core direct wiring dual NPN output 2M line | ||

OX-R1-FP-S-P1 | 4-core direct wiring dual PNP output 2M line | ||

OX-R1-EN-S-P1 | 6-core direct wiring dual NPN output with cascade 2M line | ||

OX-R1-EP-S-P1 | 6-core direct wiring dual PNP output with cascade 2M line | ||

OX-R1-FN-D-P1 | 4-core direct wiring dual NPN output 2M line, Actuator with unique code | ||

OX-R1-FP-D-P1 | 4-core direct wiring dual PNP output 2M line, Actuator with unique code | ||

OX-R1-EN-D-P1 | 6-core direct wiring dual NPN output with cascade 2M line, Actuator with unique code | ||

OX-R1-EP-D-P1 | 6-core direct wiring dual PNP output with cascade 2M line, Actuator with unique code | ||