What Is a Photoelectric Sensor?

Authoritative Definition of a Photoelectric Sensor

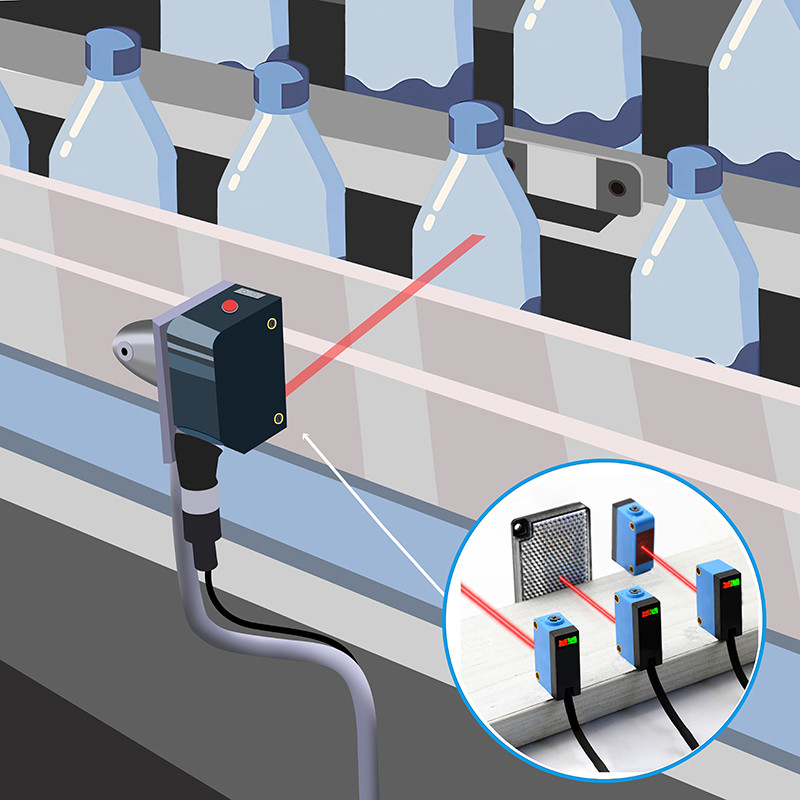

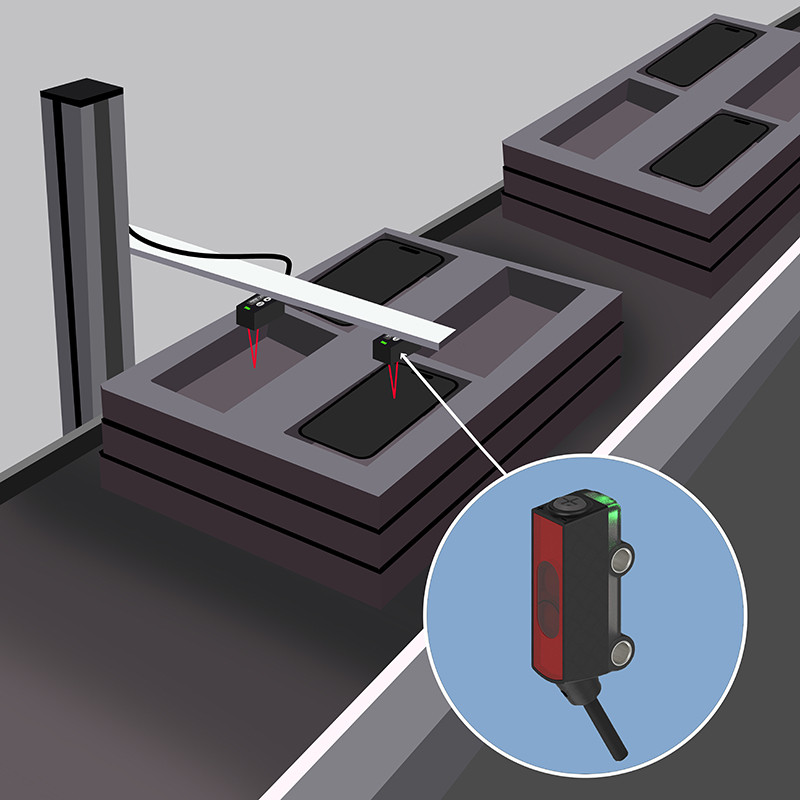

How a Photoelectric Sensor Works

Typical Technical Specification Ranges of Photoelectric Sensors

| Technical Parameter | Typical Range | Practical Meaning |

| Sensing Distance | 10 mm – 30 m | Determines maximum detection range |

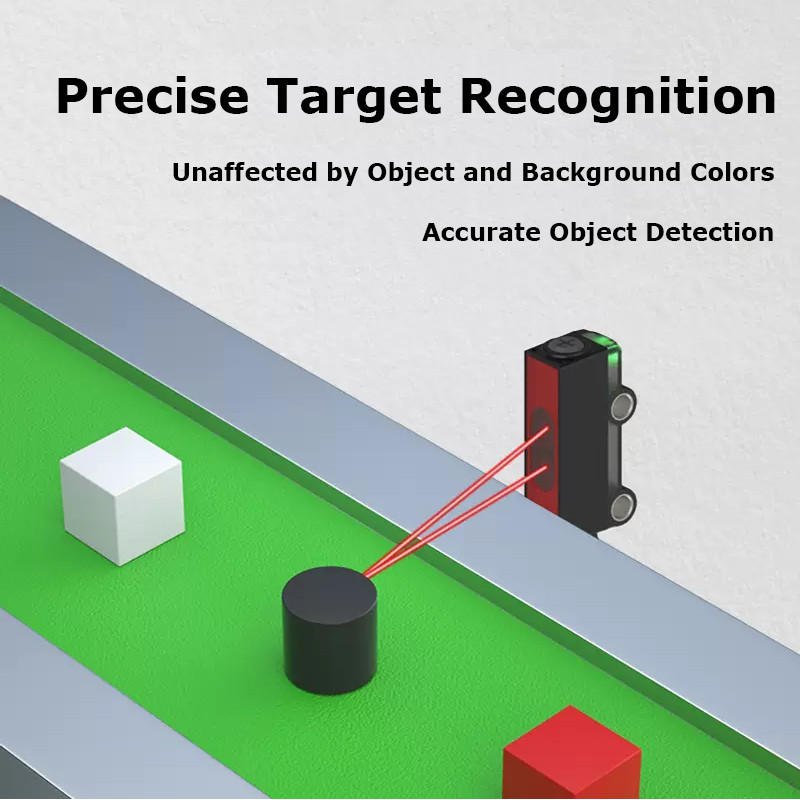

| Light Source | Infrared / Red LED / Laser | Affects accuracy and surface adaptability |

| Response Time | 0.5 ms – 5 ms | Impacts detection speed in high-speed systems |

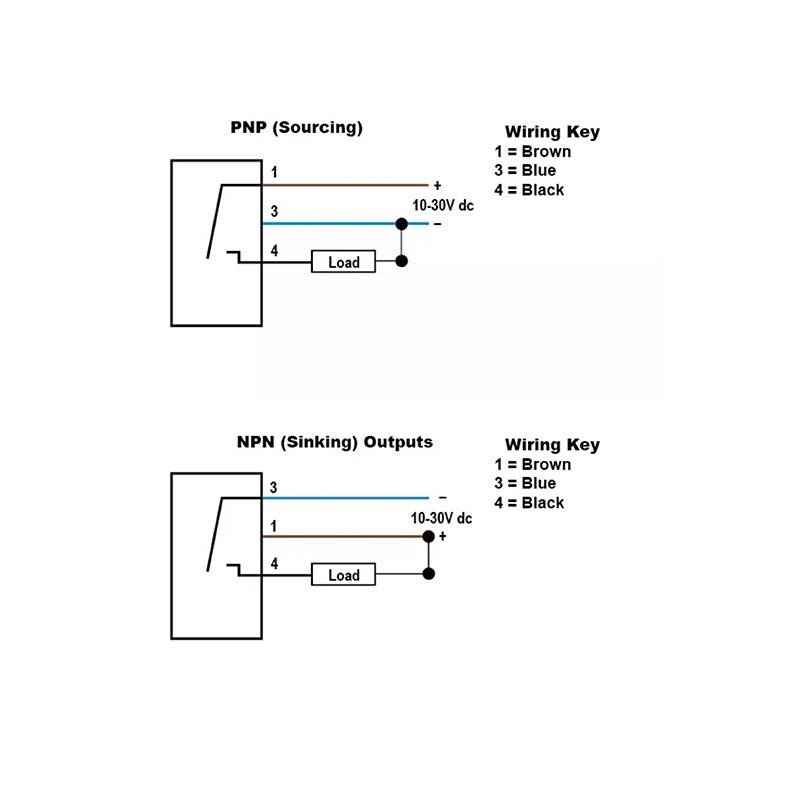

Output Type | NPN / PNP / Relay / IO-Link | Defines controller compatibility |

Supply Voltage | 10–30 V DC | Standard industrial power range |

Protection Rating | IP65 – IP67 | Environmental resistance level |

Ambient Light Immunity | ≥ 10,000 lux | Ensures stable operation under strong lighting |