Quality Standards

With a dedicated focus on industrial production assurance for 18 years, DADISICK has pioneered the 'Product Reliability Laboratory.' This includes innovative testing such as vibration tests, impact tests, waterproof and dustproof tests, and lifespan stability tests. All aimed at creating safety light grids with superior performance, stable operation, and user-friendly functionality. Every product set undergoes rigorous testing to ensure integrity before being dispatched.

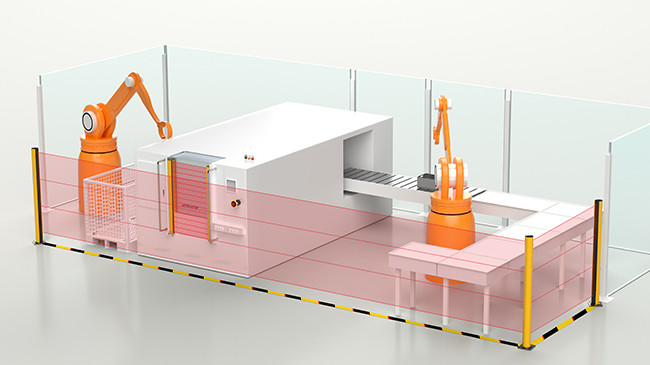

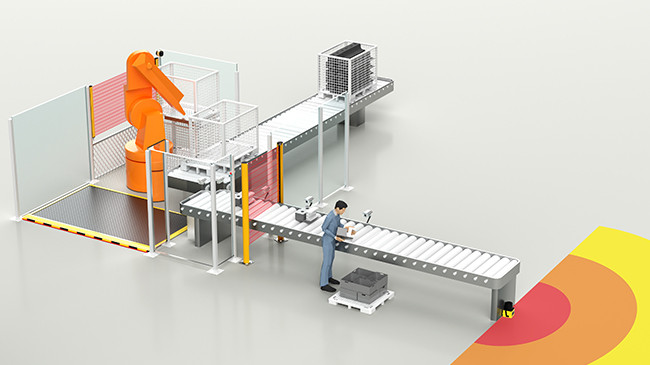

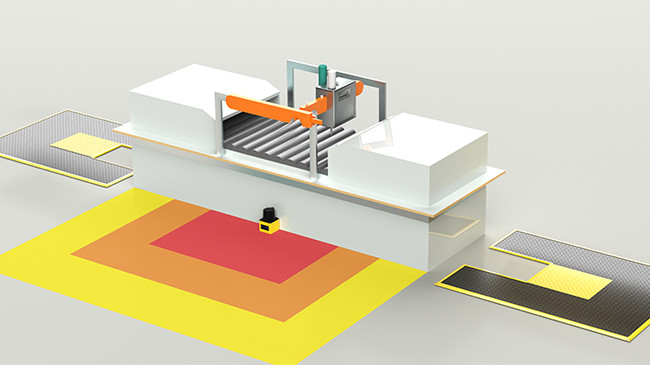

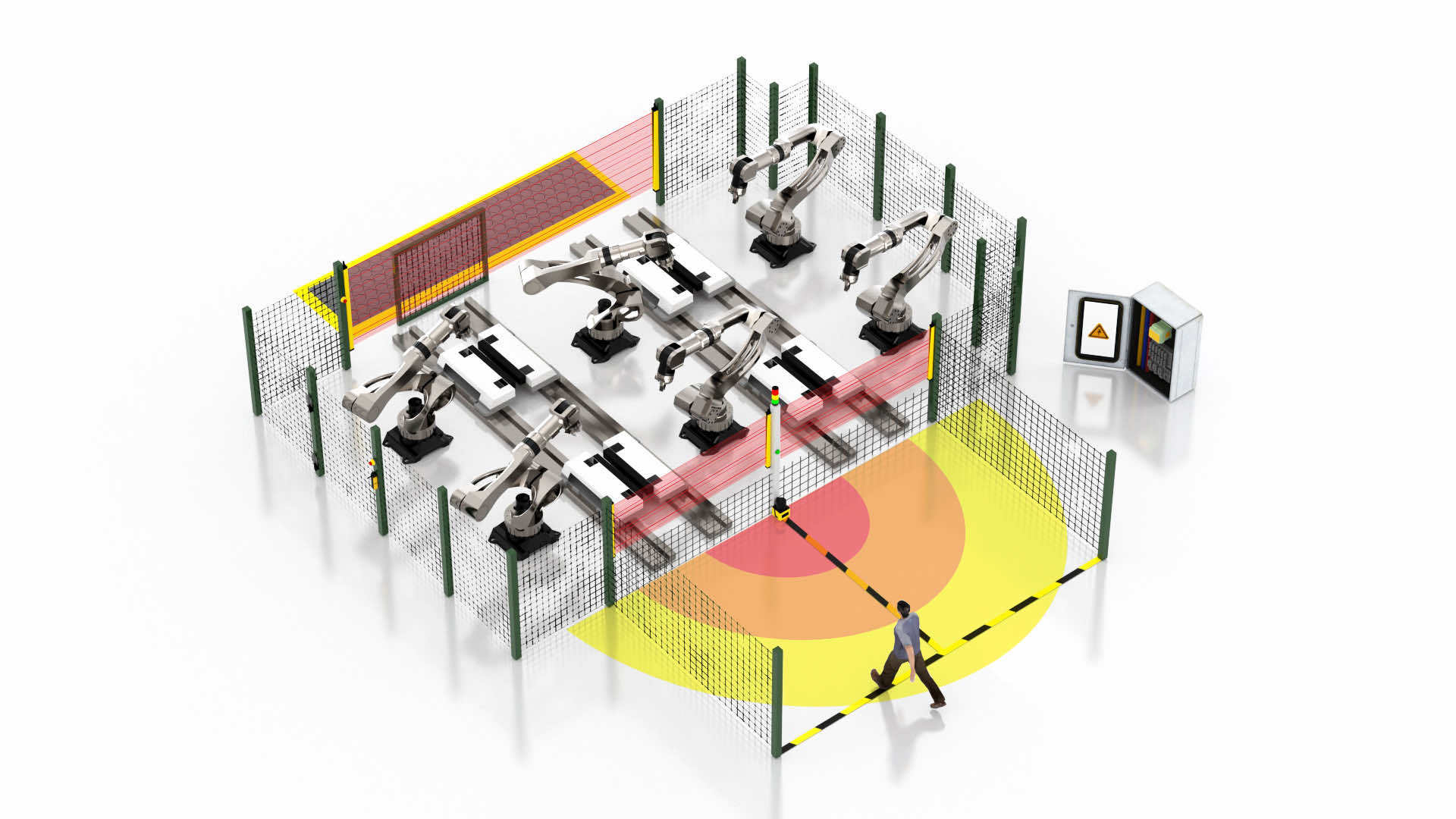

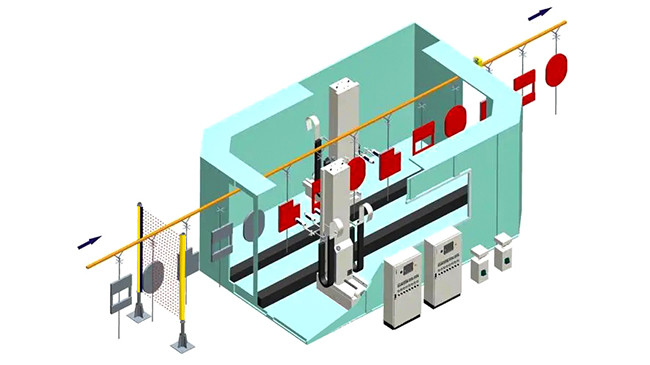

Rich Case Studies

Over the past 18 years, DADISICK has been dedicated to technological research and development, product innovation, and practical applications. With a wealth of on-site manufacturing and automation knowledge, we provide support to our customers. Our commitment lies in the development of safety protection enterprises focused on preventing stamping accidents in production. This commitment drives continual innovation and expansion of our product range.

Research and Development Technology

DADISICK is continuously committed to addressing the technical challenges and critical issues in our customers' markets. To meet elevated customer demands, we ensure high stability, precision, and performance in our products. All aimed at creating safety light grids with superior performance, stable operation, and user-friendly functionality.

Extensive Product Line

With a diverse range of products, we not only offer our own 2000 DADISICK products but also various brand alternatives to cater to your personalized needs. Our sales engineers are ready at all times to provide comprehensive support across all aspects of your business. From the design and research phases to model selection, on-site guidance, and operational assistance after product adoption in the production line, we are here for you.