How to Wire and Use a Photoelectric Sensor | GM12 Series Guide

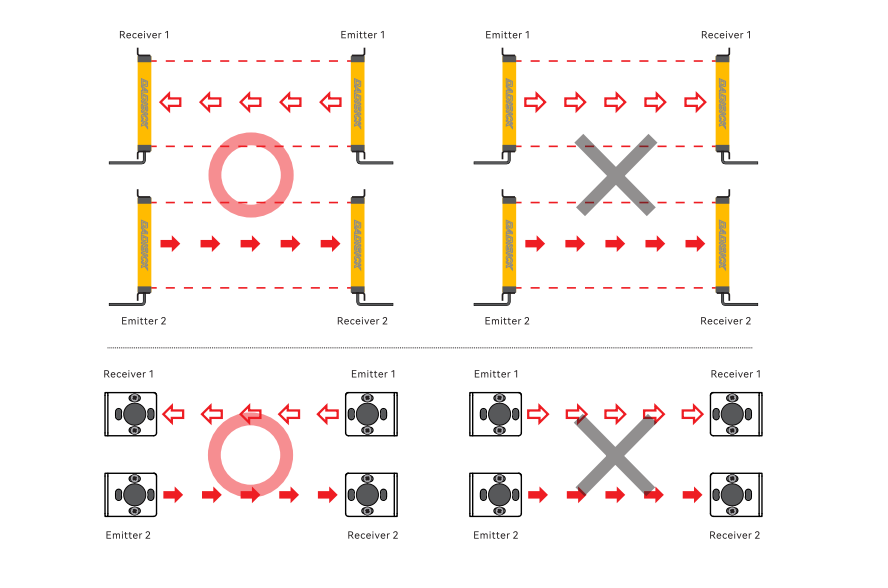

What Is a Photoelectric Sensor and How Does It Work?

GM12 Series Photoelectric Sensor Overview (Example)

How to Wire a Photoelectric Sensor (GM12 Series Example)

Fail-Safe Behavior by Default

Continuous Monitoring of the Safety Loop

Compliance with International Safety Standards

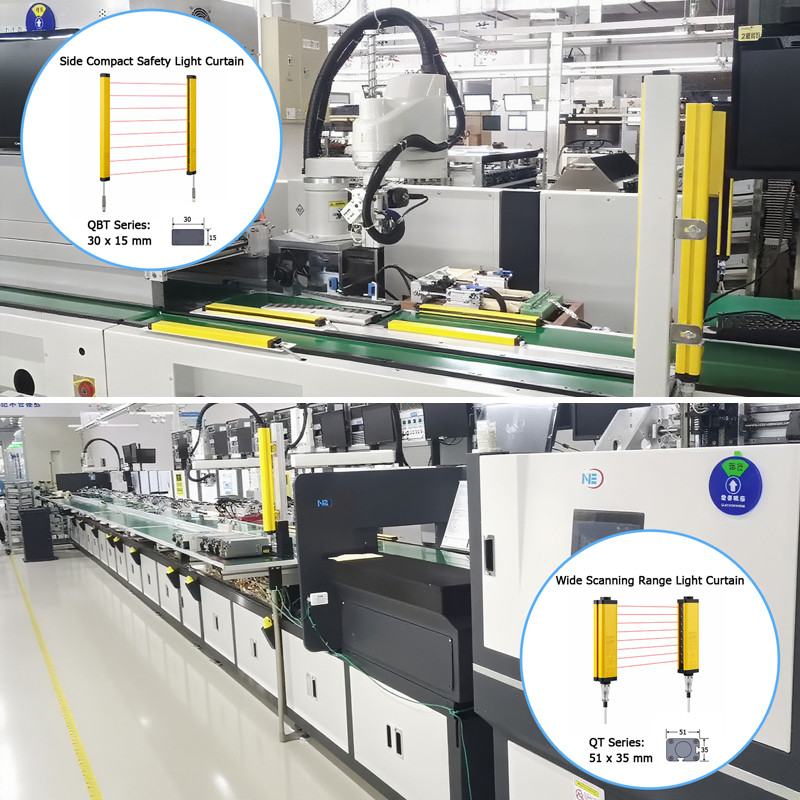

Installation and Commissioning Tips

| Feature | Normally Closed (NC) | Normally Open (NO |

| Default state | Closed (monitored) | Open (not monitored) |

| Power loss response | Immediate safe stop | Uncertain |

| Cable break detection | Instant | Often undetected |

Suitability for safety systems | Guaranteed | Not guaranteed |