Industrial Safety Mat Sensors for Machine Protection: Crush-Proof, Durable, and Ready for Automation Safety Systems

What Are Industrial Safety Mats for Machines?

A Pressure‑Sensitive Safety Device

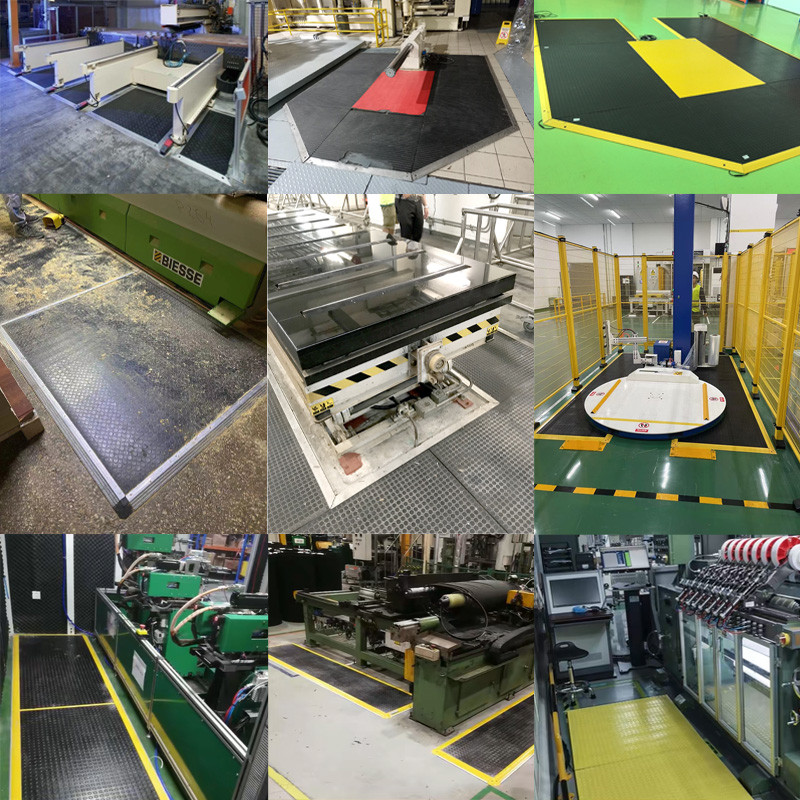

Applications of Safety Mats for Machines

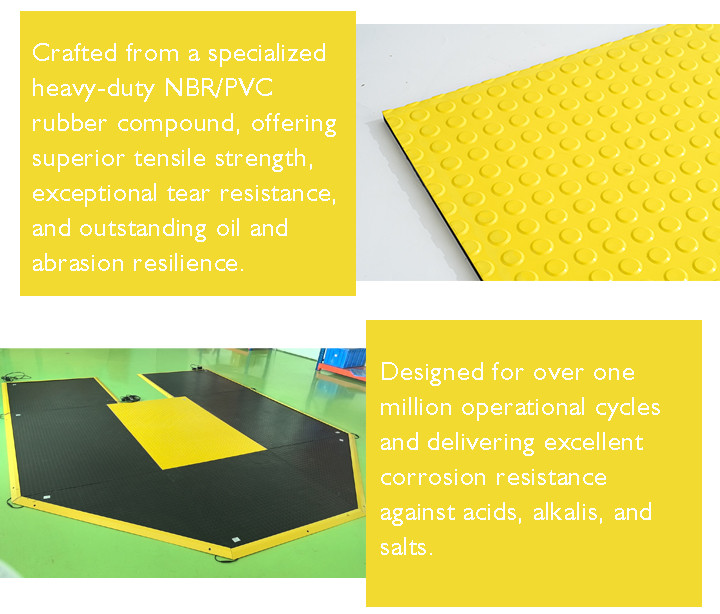

Core Features of Industrial Safety Mats

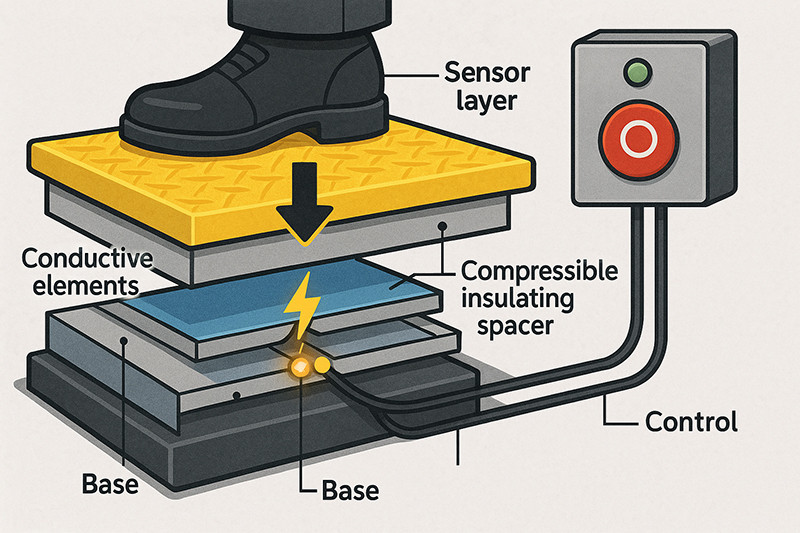

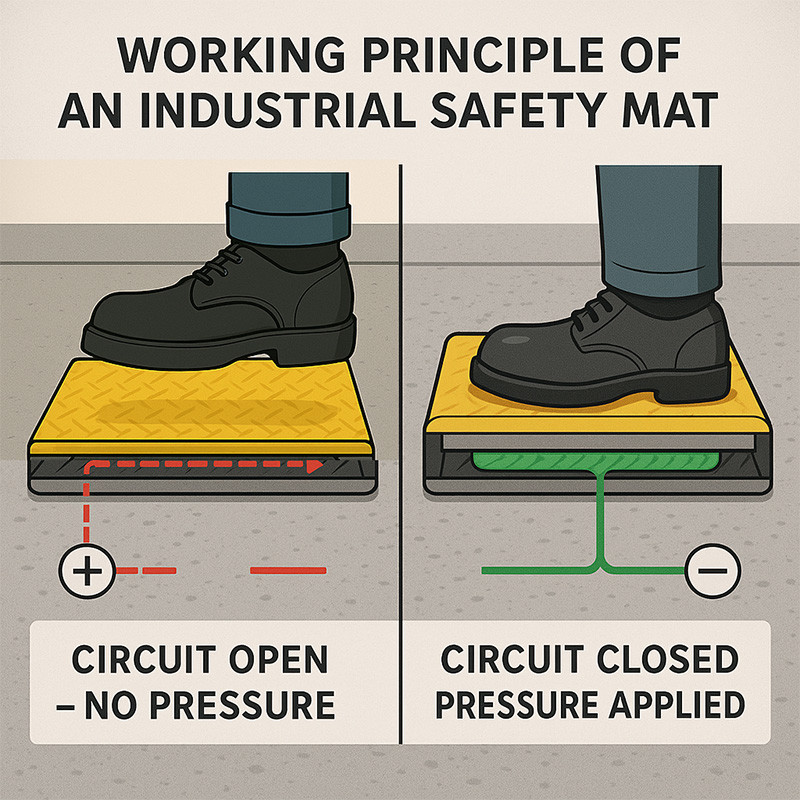

How Safety Pressure Mats Work

The Principle of Pressure-Sensitive Detection

Key Components and Mechanism

Types of Sensor Mechanisms

Integration of Industrial Safety Mats in Machinery

Layout Planning for Safety Mats for Machines

Collaborative Safety: Safety Switch Mats and a Comprehensive Safety Network

Installation and Wiring Guide for Industrial Safety Mats

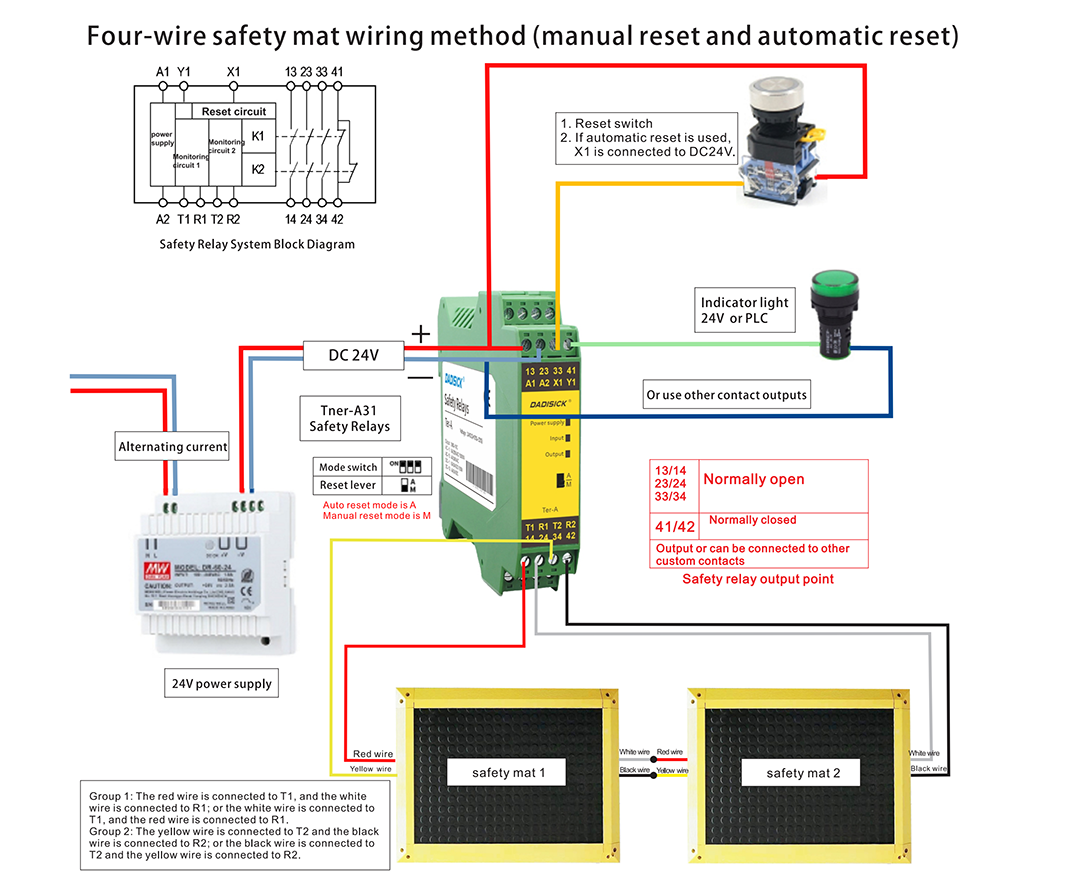

Overview of Safety Mat Wiring Principles

Example Analysis of Safety Mat Wiring Diagram

1. Four-Wire System

3. Wiring Diagram Example

Consider the DT14 series safety mat (Normally open type) and Ter-A safety relay as an example. The DT14 mat is designed for durability and sensitivity (trigger force: 30 kg), while the Ter-A relay supports versatile safety inputs and reset options.

Key Wiring Guidelines for Safety Mats

Common Troubleshooting Tips

Fault Phenomenon | Possible Causes | Troubleshooting Methods | |||

No Response When Stepping on the Safety Mat | 1. Power not connected or insufficient voltage | Use a multimeter to measure the power supply voltage (DC 24V ±10%) and check if the power switch is functioning properly. | |||

| 2. Loose or disconnected wiring | Check the terminal block and plug connections for looseness. Use a multimeter continuity test to check the cables. | ||||

| 3. Internal sensor failure in the mat | Short the mat’s output terminals. If the device stops, the internal circuit of the mat is faulty and the mat needs to be replaced. | ||||

Indicator Light Not On (if available) | 1. Fuse blown | Replace the fuse with one of the same specifications. Check the circuit for short circuits (e.g., exposed wires touching ground). | |||

2. Indicator light failure | Measure the voltage across the indicator light. If voltage is present but the light is off, replace the indicator. | ||||

1. Electromagnetic Interference

III. Device Does Not Reset After Triggering

Industrial Safety Mats Performance Testing

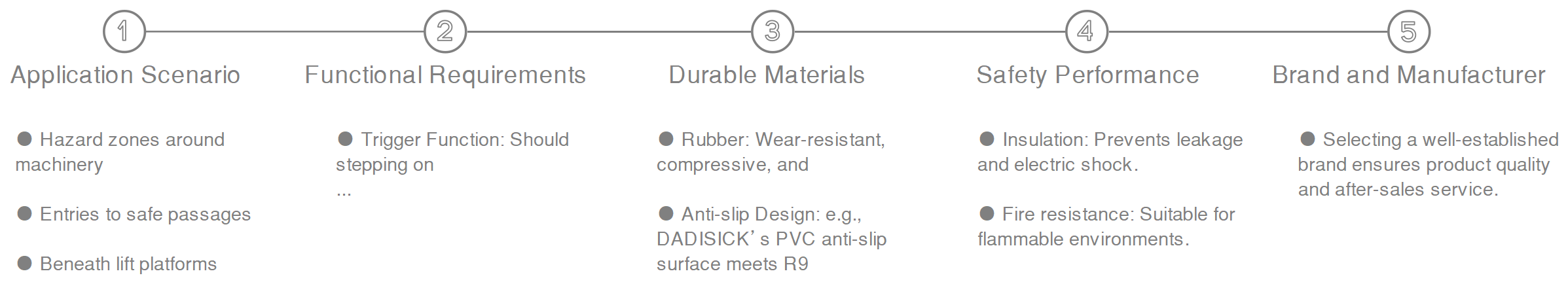

Industrial Safety Mat Selection and Purchasing Guide

| Specifications | |||

| Trigger Force | >20 kg | 30 kg (for adults) | |

| Weight | Maximum Allowable Load (8 hours): ≤ 400 N/cm² | Maximum Allowable Load (8 hours): ≤ 200 N/cm² | Pressure Resistance:

Dynamic load up to 500 kg

Static load up to 700 kg |

| Safety Mat Thickness | 15 mm | 11 mm | 14 mm |

Surface Material | NBR rubber | PVC | NBR rubber |

Mechanical life | 3,000,000 times | 1,000,000 times | 1,000,000 times |

Degree of protection | IP65 | ||

Ambient temperature | -10℃ ~ +55℃ | +5℃ ~ +55℃ | -10℃ ~ +60℃ |

Response time | 18 ms | < 30 ms | |

Recommended applications | Special or heavy-duty working conditions | General working conditions; | Safety protection for people,

small cars and vehicles in mixed areas |