Complete Guide to EN ISO 13849-1 Functional Safety for Modern Machinery | DADISICK

Ensuring functional safety is a core requirement in modern machinery design. Among all international standards, EN ISO 13849-1 is one of the most widely adopted frameworks for designing, evaluating, and validating safety-related control systems. This guide provides a clear, practical overview of the standard—and introduces how high-quality components, such as DADISICK safety sensors, can support compliance and improve machine protection.

What Is EN ISO 13849-1?

EN ISO 13849-1 defines the requirements for the design and integration of safety-related parts of control systems. It evaluates how reliably a machine's safety function performs, ensuring that hazards are reduced to an acceptable level. The standard applies to virtually all machinery, including:

· Packaging machines

· Presses and cutting equipment

· Assembly and robot stations

· AGVs and automated production lines

The goal is simple: to prevent accidents by ensuring the safety function works when needed.

The Role of Safety Functions

A safety function is any control action that helps prevent or mitigate a hazardous situation. Examples include:

· Emergency stop functions

· Guard monitoring on doors and fences

· Presence detection using safety light curtains or scanners

· Two-hand control units

· Safe speed or safe motion monitoring

Each function must be designed so that failures do not lead to unacceptable risk. EN ISO 13849-1 provides a structured method for evaluating the reliability of each function individually.

Understanding Performance Levels (PL a–e)

A major element of EN ISO 13849-1 is the Performance Level (PL) classification, which ranges from PL a (the lowest safety integrity) to PL e (the highest). The PL required depends on the machine's risk assessment, which considers severity, frequency, and probability of avoiding a hazard.

A safety system's PL is influenced by:

· Architecture Category (B, 1, 2, 3, 4)

· Diagnostic Coverage (DC)

· Mean Time To Dangerous Failure (MTTFd)

· Common Cause Failures (CCF)

To achieve the correct PL, choosing certified and reliable safety components is critical.

➡ For machinery requiring PL c to PL e safety levels, Dadisick provides specialised components such as safety light curtains, safety relays, and interlock switches designed for high diagnostic coverage.

✅Explore Dadisick Safety Light Curtains:

How to Determine the Required Performance Level (PLr)

Determining PLr is a crucial step in early machine design. It ensures that engineers understand the reliability requirements of each safety function before selecting components or designing circuits.

PLr is defined by a risk assessment using three parameters:

1) Severity of Potential Injury (S)

· S1: Reversible or minor injury

· S2: Serious or irreversible injury, including death

2) Frequency and Duration of Exposure to the Hazard (F)

· F1: Low frequency or short exposure

· F2: Frequent or continuous exposure

3) Possibility of Avoiding or Limiting Harm (P)

· P1: Possible under certain conditions

· P2: Hardly possible to avoid once the hazard occurs

Using these three factors, engineers determine a required PLr (from PL a to PL e).

This PLr then guides the selection of system architecture, sensors, logic devices, and actuators capable of meeting the required reliability.

How to Design a Safety System According to EN ISO 13849-1

To comply with EN ISO 13849-1, designers must follow a structured process:

1. Identify hazards and define safety functions

2. Determine required PL (PLr)

3. Design system architecture

4. Select appropriate safety components

5. Calculate and verify PL

6. Validate the entire safety function

Using high-quality, stable components greatly simplifies design and verification.

➡ Dadisick's QT-Series safety light curtains and OX-W2 safety interlock switches offer stable response times, built-in fault monitoring, and clear wiring documentation—making them ideal for ISO 13849-1 compliant machine design.

✅View Dadisick Safety Interlock Switches: https://www.dadisick.com/products2127641/Safety-Interlock-Switch-Devices.htm

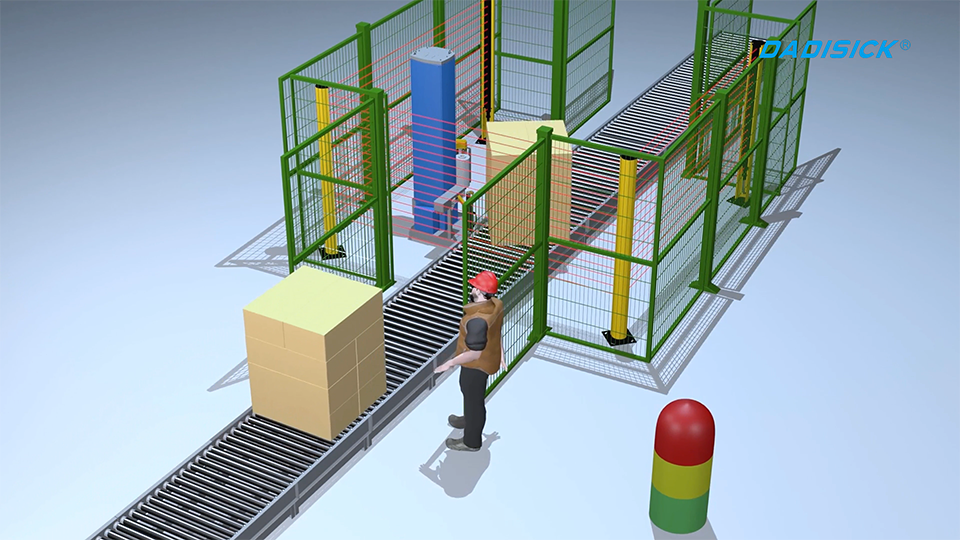

Risk Reduction Measures: Practical Implementation

Risk reduction often relies on engineering controls, particularly where operator access or machine motion poses a risk of harm. ISO 13849-1 accepts a wide range of protective devices:

· Safety light curtains

· Interlock door switches

· Safety relays and controllers

· Laser area scanners

· Mechanical guards combined with safety sensors

These devices ensure hazardous movements stop immediately when a safety condition is violated.

➡ Dadisick provides comprehensive optoelectronic safety solutions—including wide-range light curtains, industrial safety door switches, and laser scanners—widely used in packaging lines, robots, and industrial automation.

✅See All Dadisick Machinery Safety Solutions: https://www.dadisick.com/comm17/Industrial-Automation-Safety-Solutions.htm

Validating the Safety System

Validation (as required by EN ISO 13849-2) ensures the final design meets the intended PLr.

This includes:

· Checking system architecture and reliability calculations

· Testing safety functions in real operating conditions

· Ensuring that all foreseeable failures have been addressed

Validation is essential not only for compliance but also for ensuring long-term safety performance.

Typical Applications of Systems Conforming to ISO 13849-1 Standard

ISO 13849-1–compliant systems are widely applied in:

· Automotive manufacturing

· AGV/AMR navigation zones

· CNC machining and metalworking equipment

· Food and beverage packaging

· Robot workstations

· Conveyor lines and sortation systems

These industries require dependable safety sensing components to protect workers and ensure smooth production.

Why Compliance with EN ISO 13849-1 Matters

Following the standard offers several key benefits:

· Regulatory compliance with machinery safety laws

· Improved workplace safety and reduced accident risk

· Reduced liability for manufacturers and integrators

· More reliable and predictable machinery performance

· Easier certification and market acceptance

In modern automation, functional safety is not optional—it is a competitive necessity.

Final Insights: Ensuring Safety and Reliability Through EN ISO 13849-1

EN ISO 13849-1 provides a clear, structured roadmap for designing safe and reliable machinery. By assessing risks, determining PLr, and validating each safety function, companies can build machines that protect workers while maintaining high productivity. Functional safety is more than a regulatory obligation—it is a commitment to trust, reliability, and responsible engineering. When paired with dependable safety components, the principles of EN ISO 13849-1 empower industries to achieve safer automation across every stage of production.

Recommended Safety Sensors Conforming to ISO 13849-1 Standard

Detection Method: Pressure sensing method

Pressure Resistance: Dynamic load up to 500kg, static load up to 700kg

Trigger Force: 30 kg (for adults)

Surface Protection Material: NBR rubber

Mat Thickness: 14 mm

Beam spacing: 2.5mm

Number of optical axes: 280

Protection height: 697.5mm

Safety Curtain outputs (OSSD):2 PNP

Detection range: 60-1000 mm

Material: copper nickel plating, plastic fittings

Connection type: 5-pin M12 connector

Output method: 2 push pulls, support IO-Link output

Used for monitoring places such as safety doors and windows.