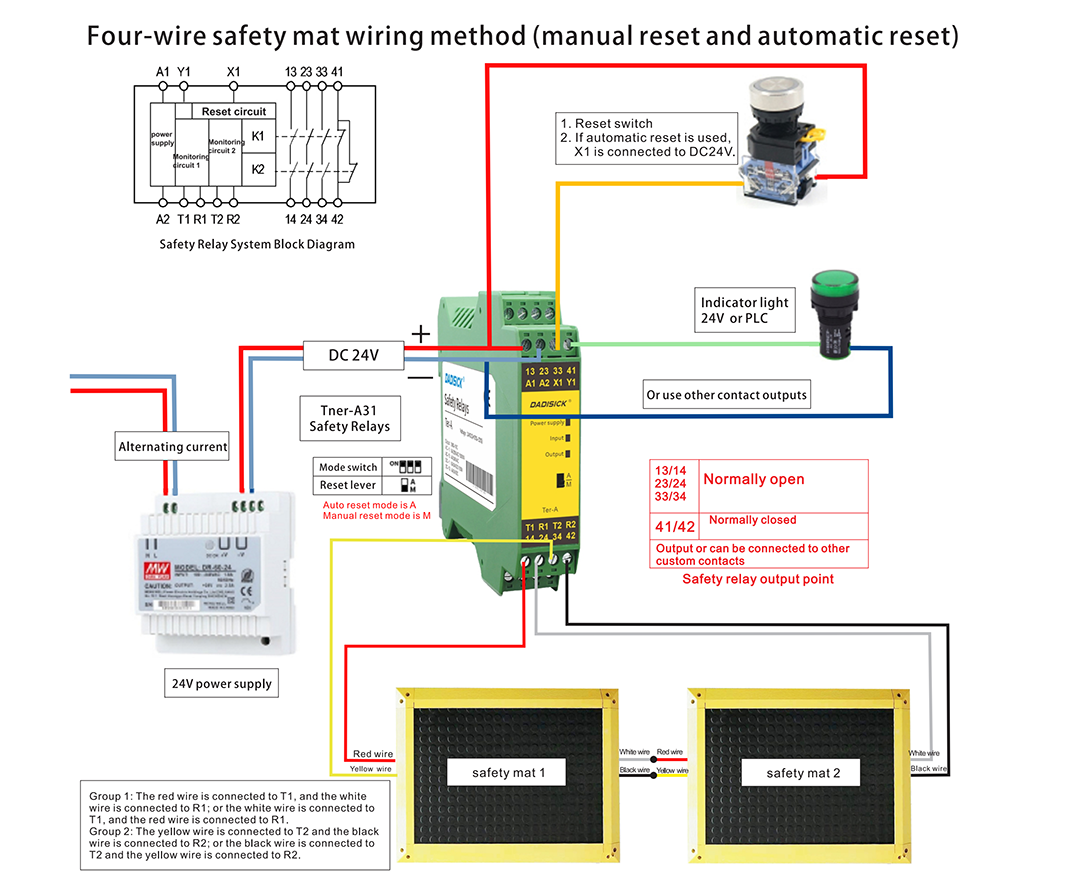

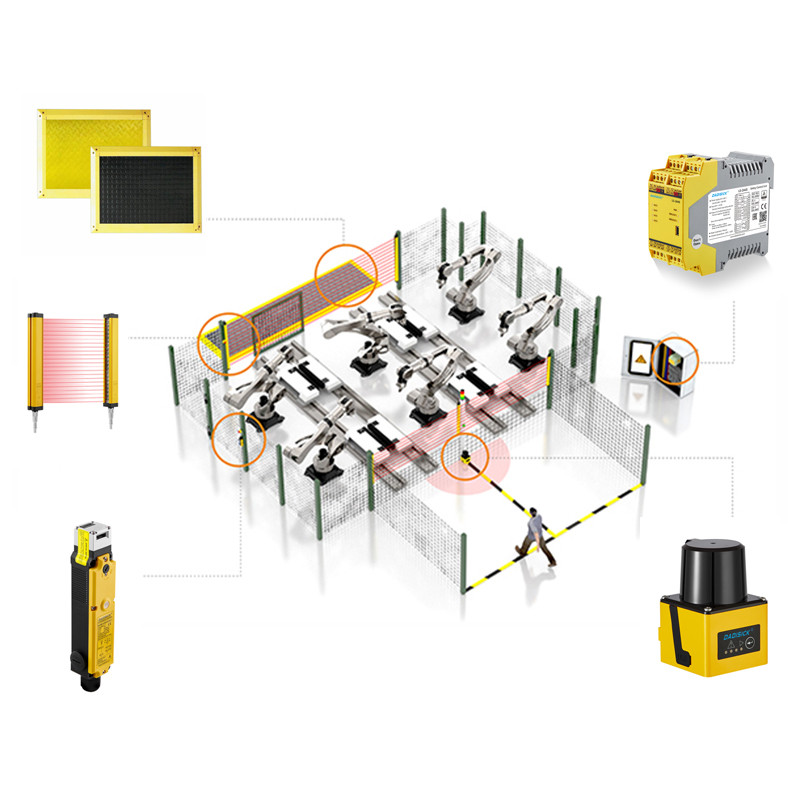

How to Use Safety Relays to Monitor Safety Mats? Wiring Diagrams and Applications

Basic Principles of Safety Mats

Why Do Safety Mats Need to Be Connected to Safety Relays?

Typical Functions of Safety Relays

| Function | Purpose | ||||

Fault Monitoring (Open/Short Circuit Detection) | Ensures circuit integrity; initiates immediate shutdown upon line abnormalities. | ||||

Dual-Channel Redundant Output | Meets high safety level requirements such as PL d/SIL 3; failure of a single path does not affect the overall system. | ||||

| Safety Stop Output | Quickly cuts off power to eliminate hazards. | ||||

| Automatic/Manual Reset | Provides flexible reset methods to prevent accidental restart of personnel or equipment in hazardous conditions. | ||||

| Bypass Prevention Design | Prevents users from bypassing the safety circuit using jumpers or other methods. | ||||

System Diagnostics and Indicator Lights | Provides real-time feedback on circuit status, facilitating maintenance and troubleshooting. | ||||

Safety Relay Wiring Examples and Industry Practices